The company area could be expanded by 70,000 sqm through the purchase of an adjacent plot of land, which enabled the construction of two new production halls.

Establishment of our own heat treatment plant to guarantee optimum quality for impact extrusions through an adapted degree of hardness.

An Italian competitor could be taken over by JAHN GmbH and integrated into the Tambach-Dietharz site together with its product range.

The company premises are expanded: the addition of a new building enables the new head office to be put into operation following extensive renovation work.

Takeover of the machinery and its orders of a Bavarian company by JAHN GmbH.

Through the purchase of new machinery and equipment as well as modern assembly technology, the production range is expanded to include systems and components made of aluminum.

In Bahnhofsstraße, the construction of a new hall for the production of systems and components made of aluminum is completed.

The production area is expanded by the addition of a new hall.

This is supported by the purchase of new machinery and equipment.

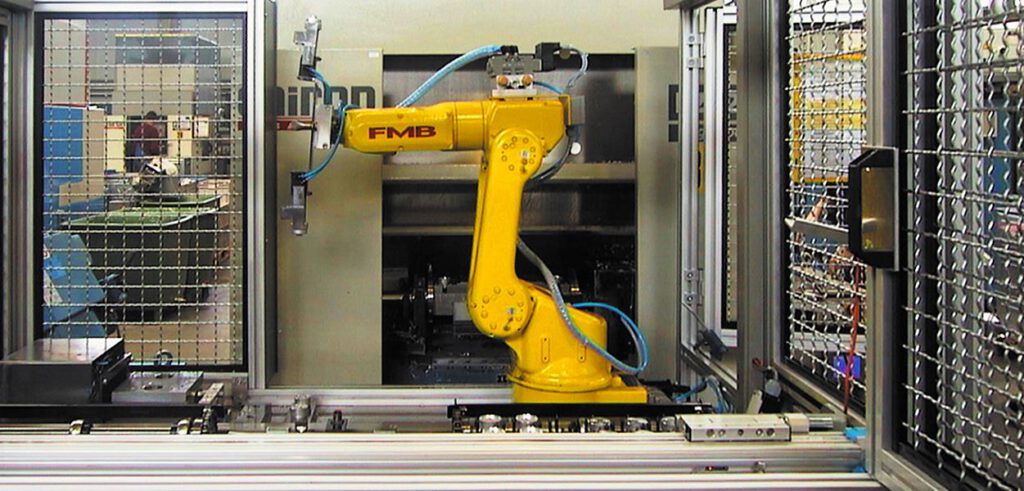

JAHN GmbH makes extensive investments in robot technology, initiating the transition to automatic operation of the CNC machining centers.

The toolmaking capacity is expanded and the construction of another three rotary table machines is completed. In addition, the purchase of two CNC lathes and the installation of a new transformer station allow further increases in capacity.

A newly acquired hall is converted for the start-up of a tool and filter production. In addition, offices, sanitary facilities, parking spaces and a transformer and compressor station are added.

In addition, a new warehouse is built between the two existing halls and further new CNC milling centers.

Old production and auxiliary buildings in Triftstraße are demolished a new building is erected as a machining center and new administration.

22 new CNC milling centers for the finishing of technical impact extrusion parts are put into operation.

The renovation of the lower Automatensaal in Triftstraße continues. In addition, construction begins on a new hall for washing and shipping, as well as new changing rooms, sanitary facilities, break rooms and offices.

A production hall is purchased from Thüringer Schraubenwerk AG to continue the production of technical impact extrusions.

Foundation with takeover of the former plant 1 of Thüringer Schraubenwerk AG in Triftstraße.

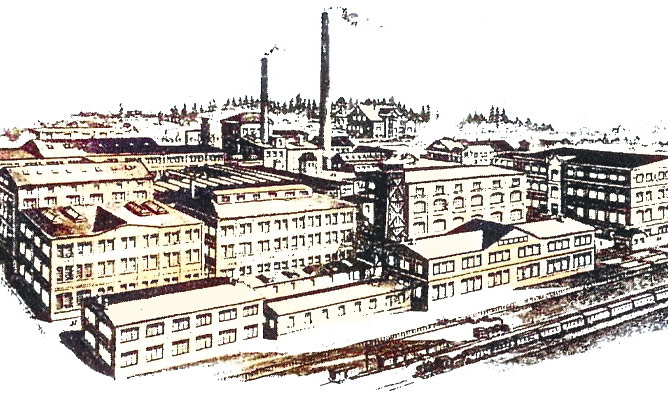

JAHN GmbH is located in Tambach-Dietharz at a site with a long tradition in metal processing. Already in 1890 it served for the metal goods factory Metz, Bauer u. Kettling as a production site for screw clamps, metal fittings and bicycle bells. The foundation of that company was also the starting point of the Tambach industry. During the period of industrial boom, the town became better known and gained more and more economic importance due to the expansion of the production variety.

In the course of the decades, further metal processing companies were founded. With these, the production of screws, tools and other metal products as well as the cold forming of steel were added in Tambach (or from 1919 in Tambach-Dietharz).

In the course of far-reaching restructuring in 1945, aluminum products were manufactured for the first time in the valley region in the Thuringian Forest with the production of aluminum tubes for medicinal ointments and toothpaste as well as aluminum sleeves for tablets. This was the first mention of the light metal, which was later to be of fundamental importance for JAHN GmbH.

In the following decades, the production program of the site was further expanded. New companies were founded and expanded, which gained GDR-wide importance in the sectors of screw production as well as wagon and vehicle construction.

With the peaceful revolution of 1989 an independence of the companies could be realized. This triggered further restructuring. In the course of this, several success stories took their course in Tambach-Dietharz. This was also the case with JAHN GmbH.

Umform- und Zerspanungstechnik

Im Grund 1-9

99897 Tambach-Dietharz

Germany

Phone: +49 36252/ 464 – 0

E-mail: info@jahngmbh.de

Our headquarters (Im Grund 1) with several conference rooms is available for visits.

Contact us for a joint appointment using our contact form.