JAHN GmbH can look back on more than 30 years of experience with aluminum products. Behind the innovations and novelties of the past – but also those of the present and future – are state-of-the-art manufacturing technologies and processes.

With the demand for concepts in line with the times, we employ more than 30 engineers and technicians who develop and research on a daily basis on various process engineering topics. In this way, we can sustainably offer the professional framework that our customers expect from us.

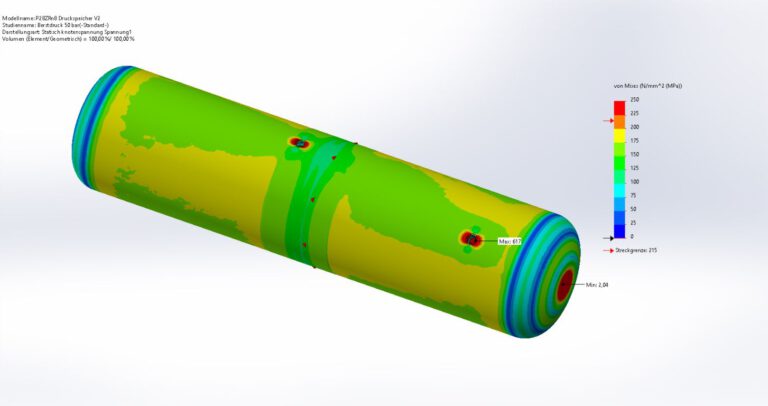

3D simulation of an asymmetric pressed part by impact extrusion process

2D simulation of a rotationally symmetrical pressed part by impact extrusion process

As a result of our work, a large number of innovative solutions have been registered as patents. These include the application areas of cooling media, storage devices and outer packaging.

Due to our lead through secured and protected knowledge, not only we but also our customers can profit directly.

In our manufacturing methods, we emphasize the best possible quality in each and every product. For this reason, we guarantee our customers certified standards that they can rely on as part of a partnership.

We see the certification of our processes as an ongoing process. Thus, in the long term, we strive to acquire further assurances of our guaranteed performance. Only in this way can we ensure the sustainable success of our customers in the long term.

Umform- und Zerspanungstechnik

Im Grund 1-9

99897 Tambach-Dietharz

Germany

Phone: +49 36252/ 464 – 0

E-mail: info@jahngmbh.de

Our headquarters (Im Grund 1) with several conference rooms is available for visits.

Contact us for a joint appointment using our contact form.